OEE Monitoring

Optimize machine efficiency effortlessly with our OEE Monitoring Dashboard. Get real-time insights into availability, performance, and quality, including production details and downtime analysis.

Machine OEE Monitoring Solutions

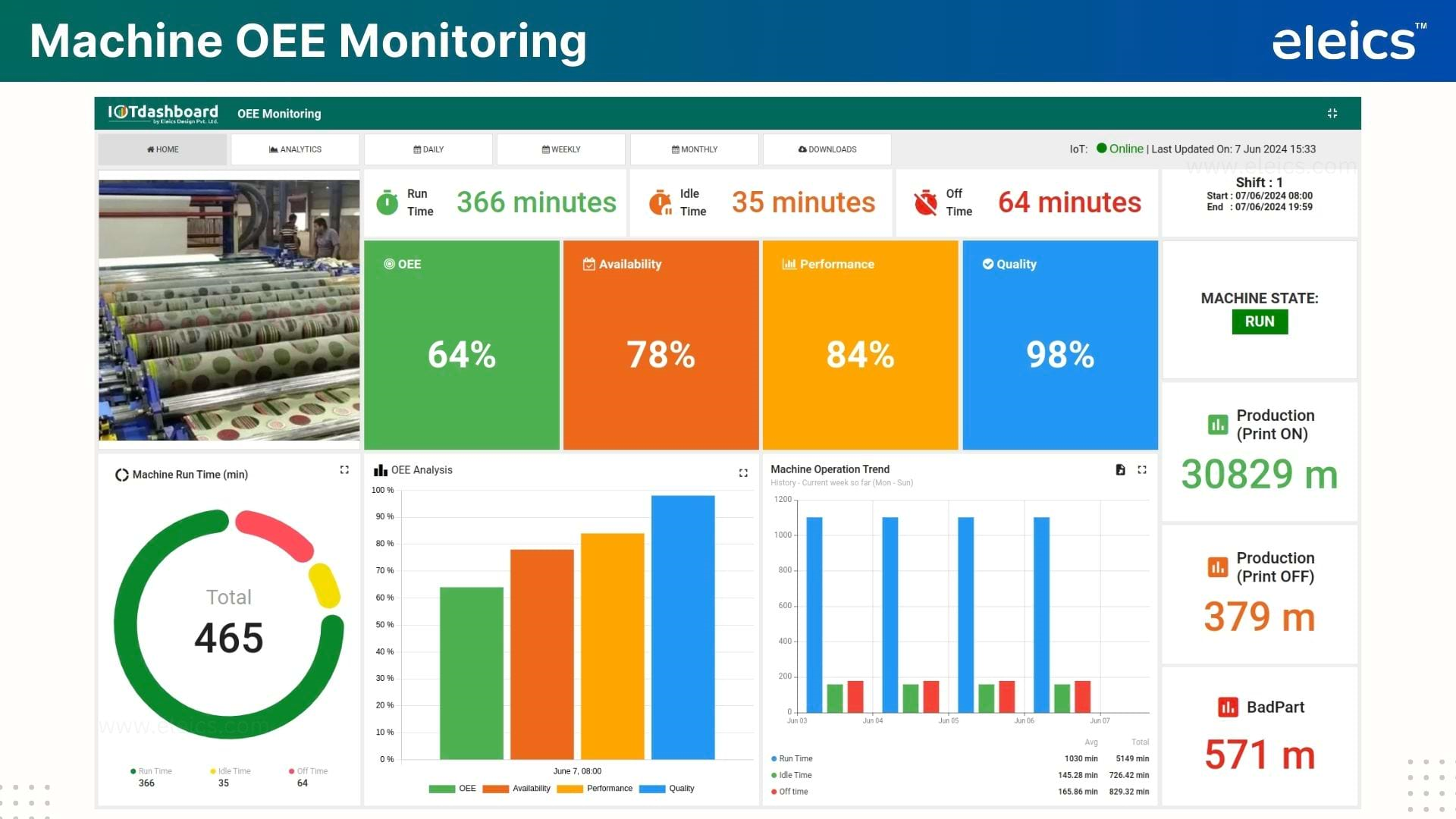

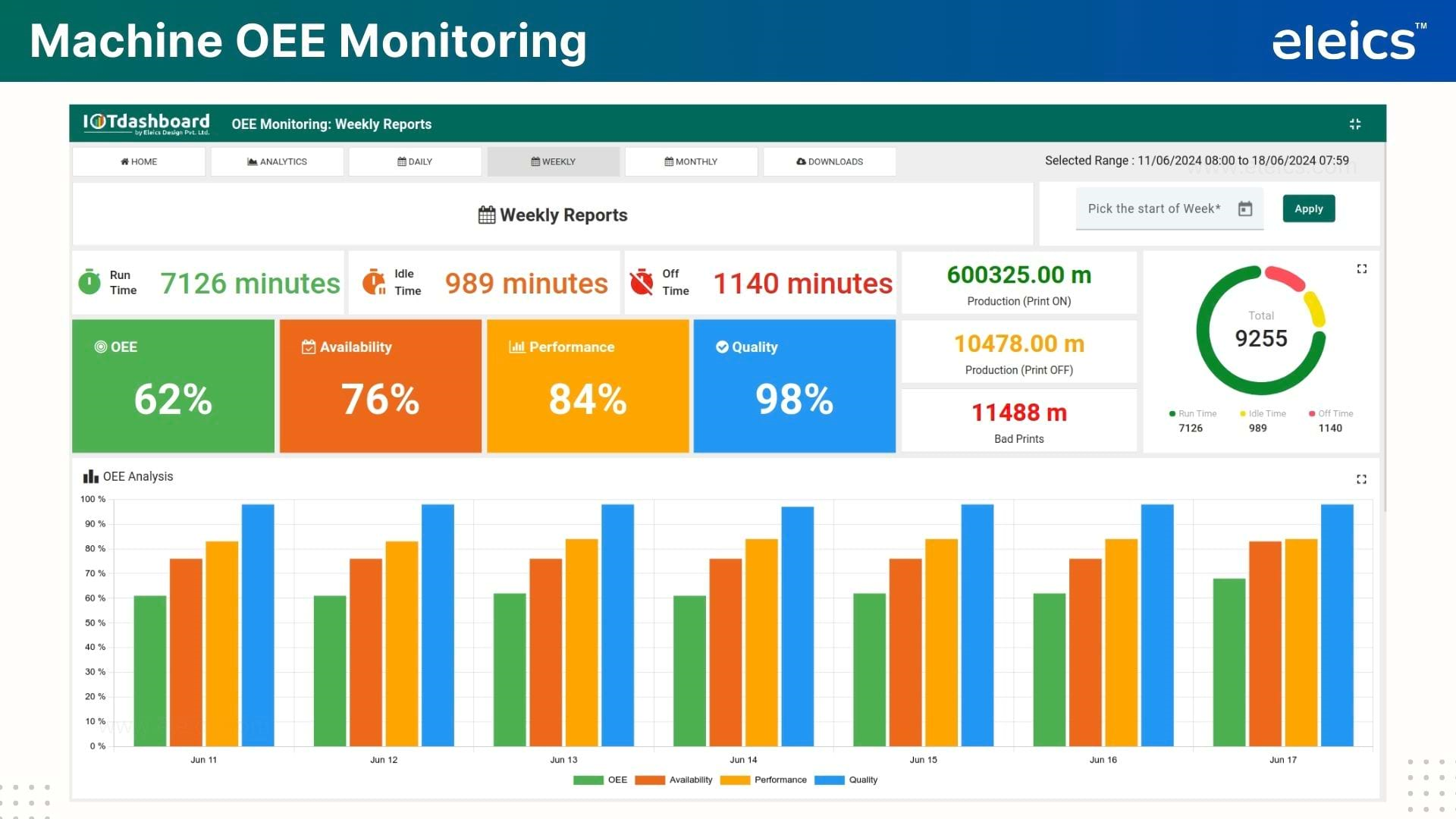

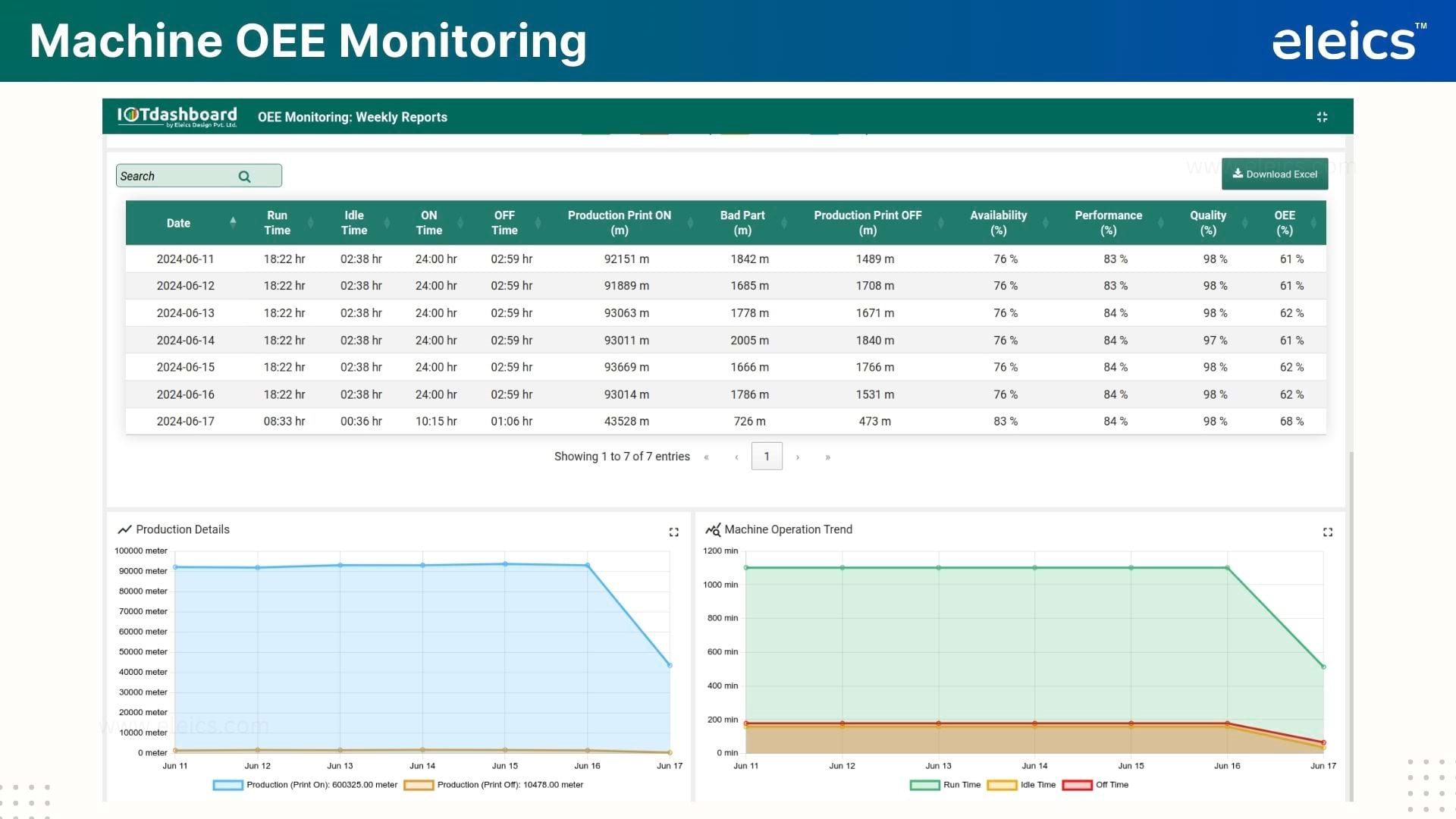

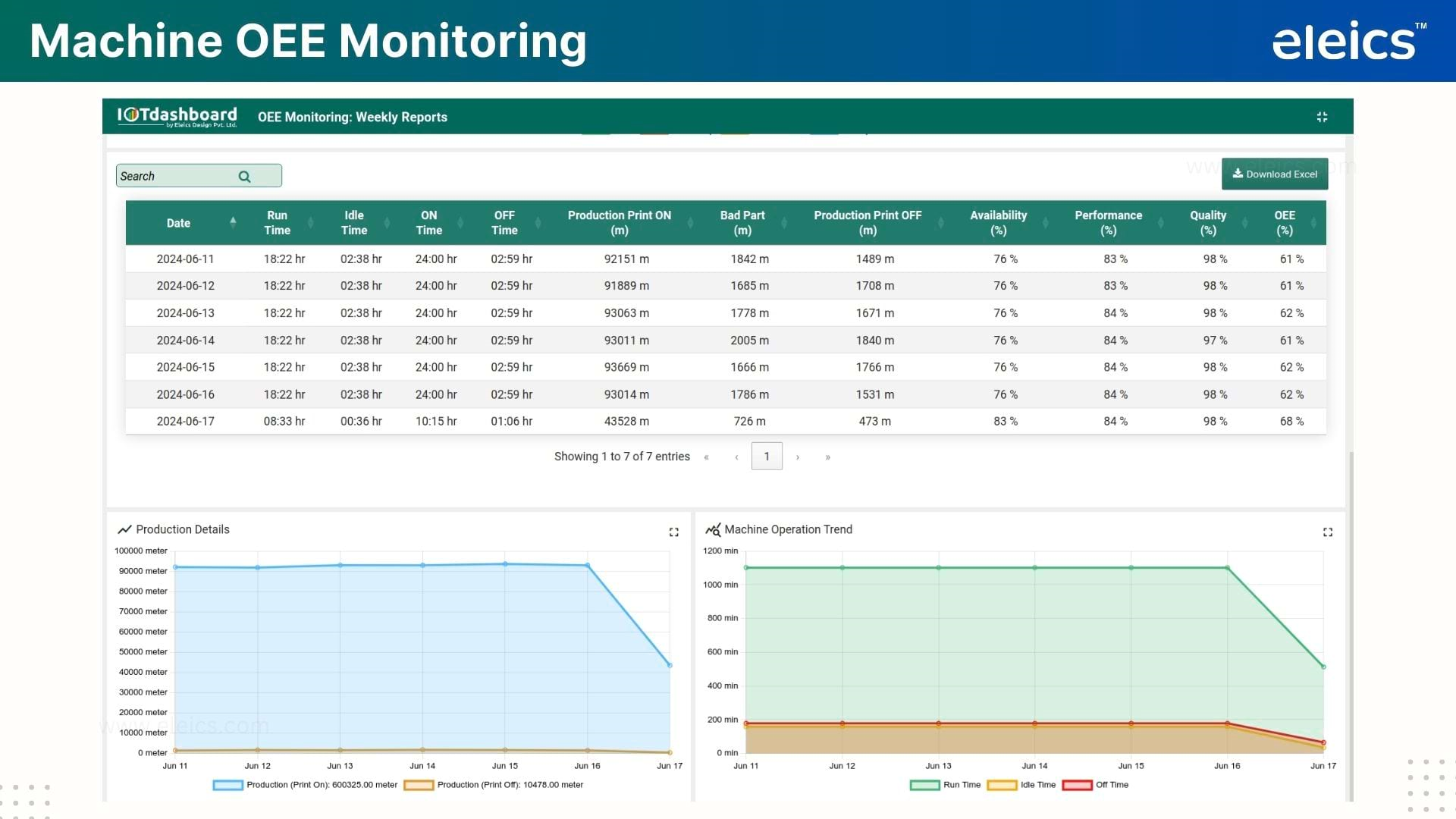

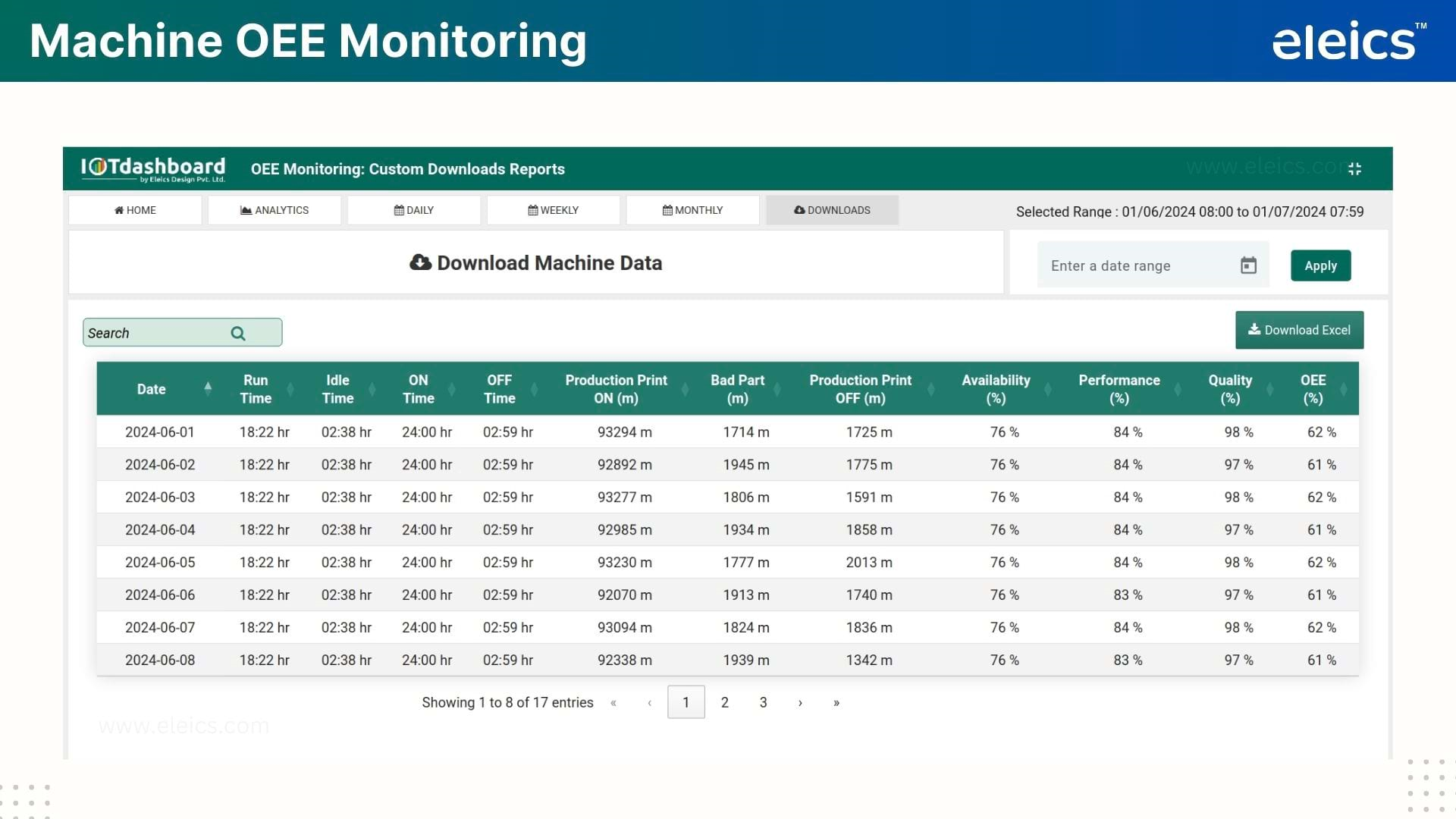

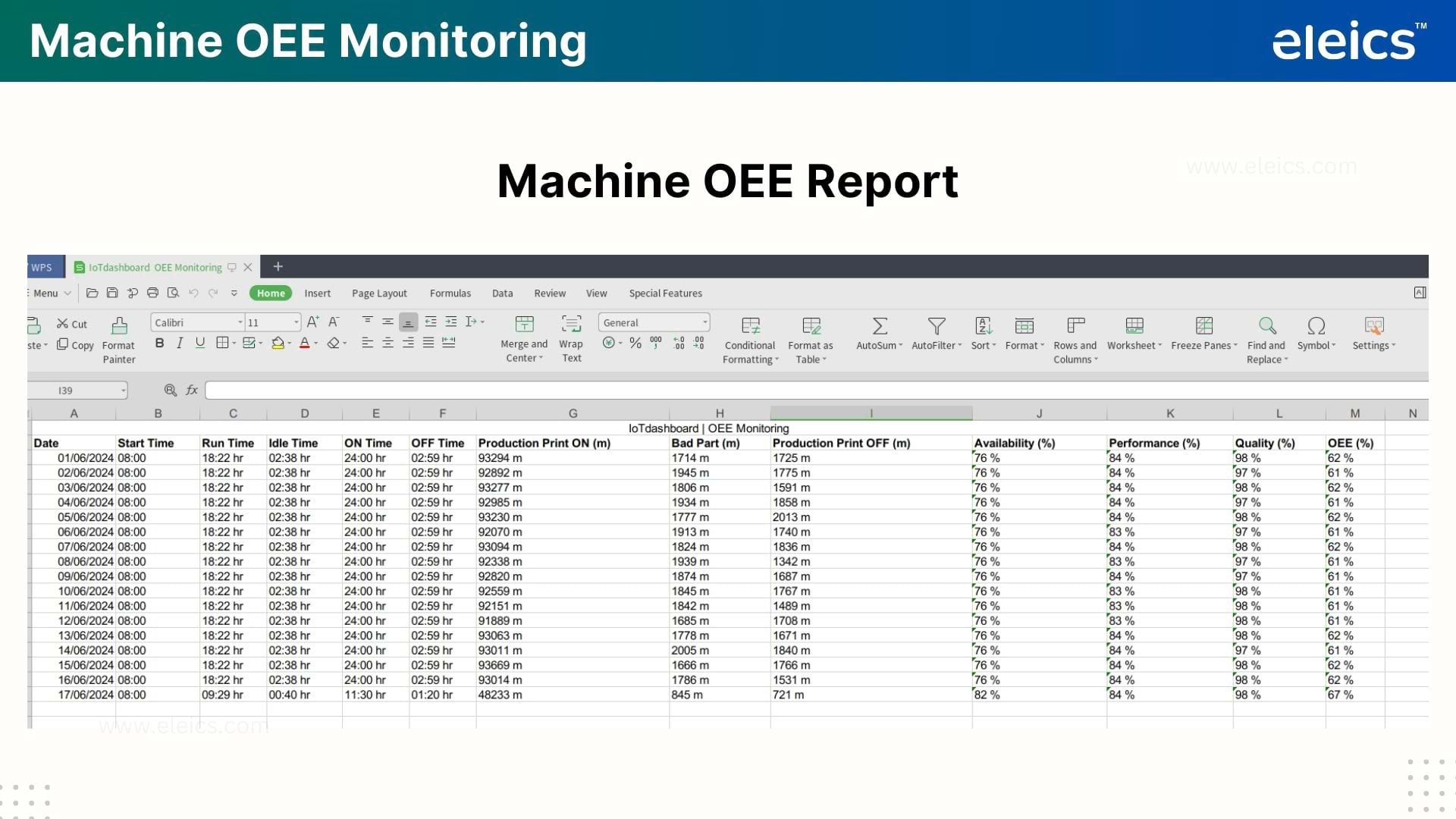

Monitoring Machine Overall Equipment Effectiveness (OEE) offers comprehensive insights into a machine's efficiency by combining availability, performance, and quality metrics. Visual representations of these metrics enable quick assessments of the machine's effectiveness and performance. Detailed operational analysis involves tracking run time, idle time, and off time across different periods (daily and shiftwise), revealing patterns and areas for improvement. Quality control is ensured through monitoring print metrics, distinguishing between good and bad prints, while analyzing production metrics provides insights into the machine's output and performance.

Benefits of Machine OEE Monitoring Solutions

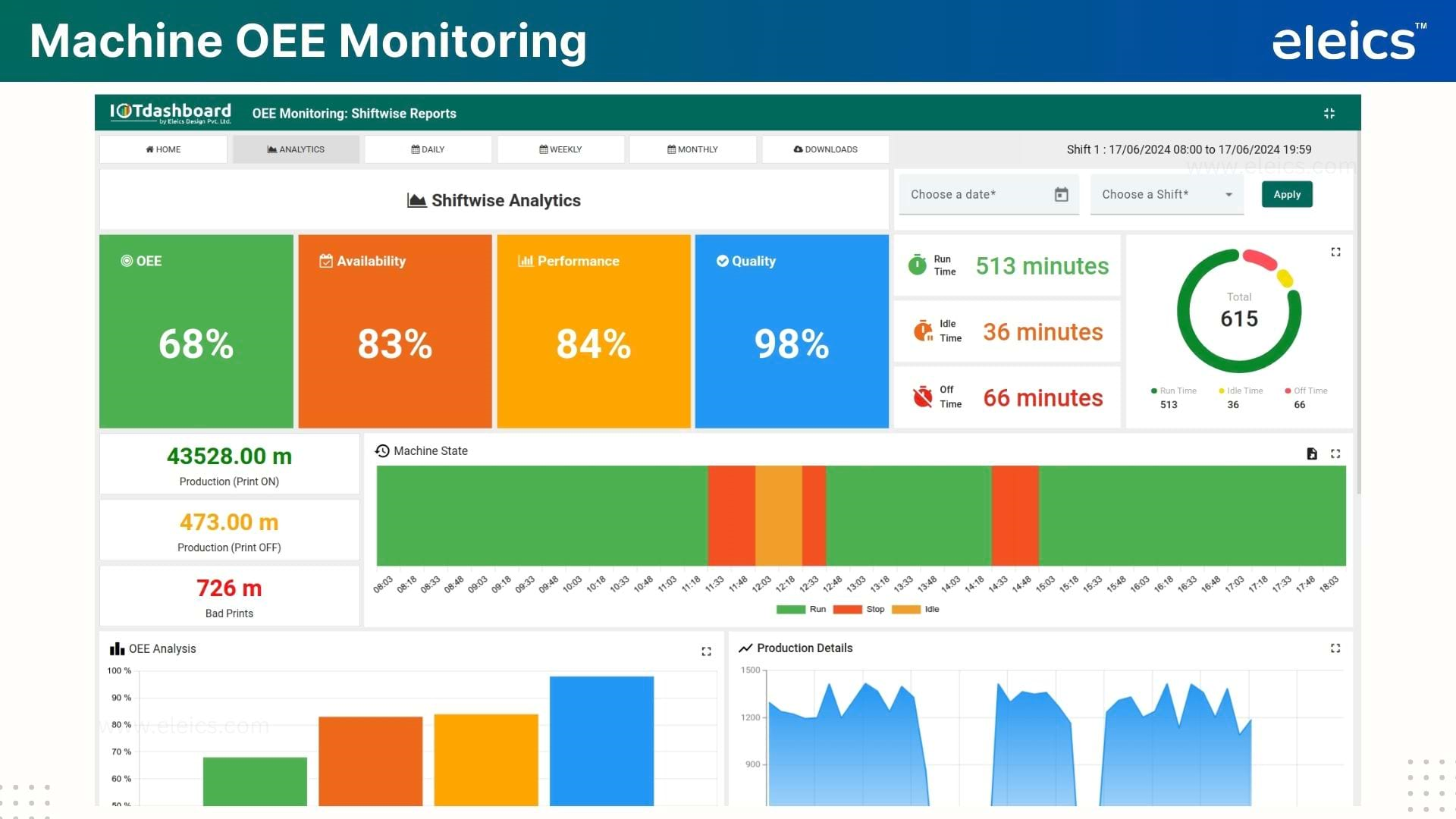

Shiftwise Performance Insights

Track machine metrics shiftwise for insights into performance variations throughout different shifts.

OEE Monitoring

Monitor Overall Equipment Effectiveness (OEE) for a comprehensive view of machine efficiency.

Visual Efficiency Assessment

Graphical representations of availability, performance, and quality percentages enable a quick and visual assessment of machine efficiency.

Detailed Operational Analysis

Track run time, idle time, and off time for today and shiftwise for a detailed analysis of machine operations.

Quality Control Metrics

Monitor print metrics, including good and bad prints, for quality control and production analysis.

Reduced operational expenses

By improving Machine efficiency and reducing waste, businesses can improve their overall productivity. This can lead to significant savings of bills and machine maintainance.

Need help?

Need help?