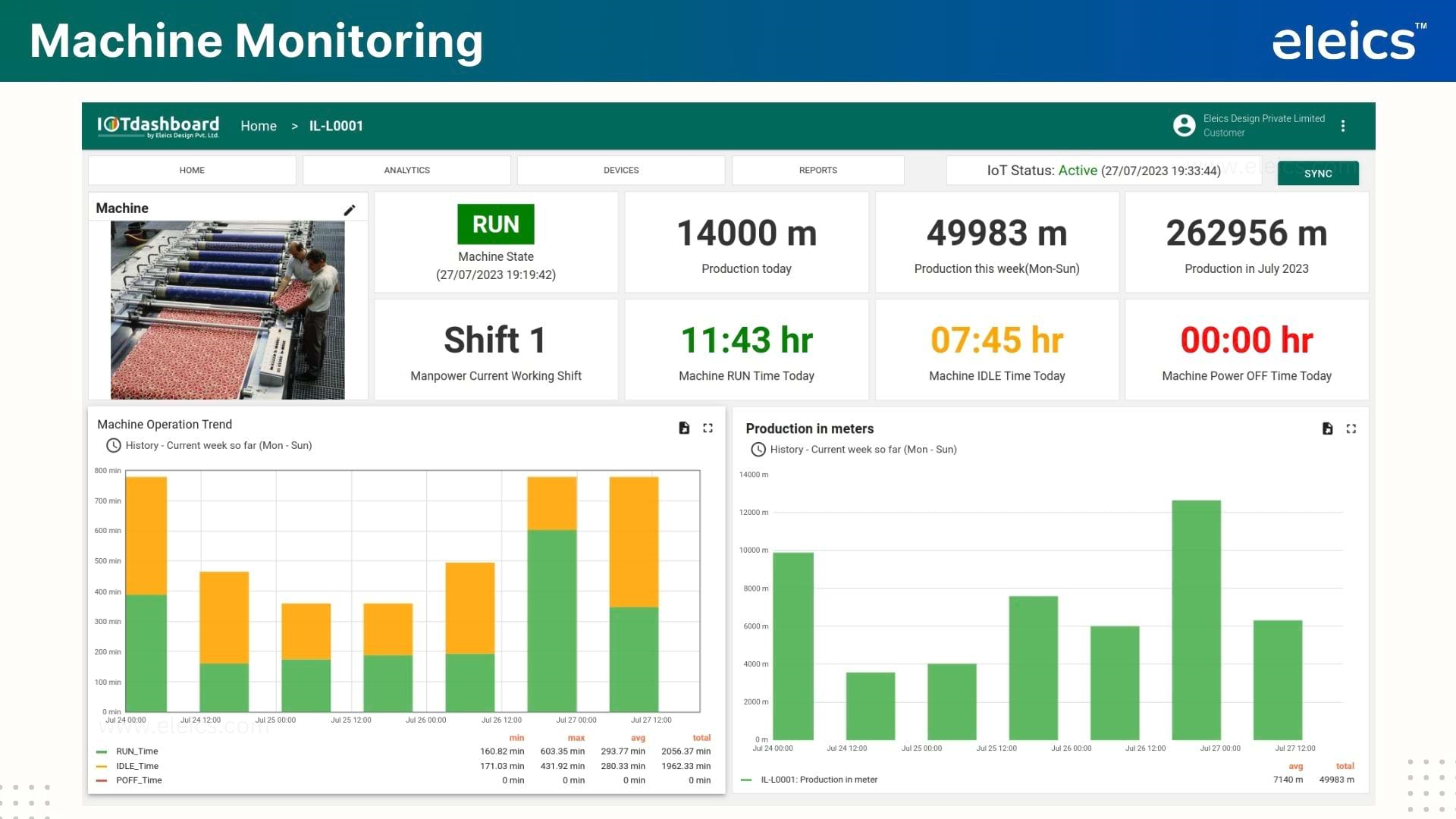

Machine Monitoring

Boost productivity and reduce downtime with Machine Monitoring, offering real-time data on equipment performance for proactive maintenance.

Machine monitoring solutions

Enhancing operational efficiency involves monitoring machine run time, idle time, and stop time to optimize performance and address factors contributing to downtime. By tracking production during both run and idle times separately, production insights can reveal machine efficiency in different operational states, aiding better production planning. Real-time state monitoring provides instant information on whether a machine is running, idle, or stopped, facilitating quick decision-making and response to machine conditions. Analyzing performance specific to the current shift offers targeted insights for immediate adjustments and improvements. Additionally, graphical trend analysis visually represents machine performance over time, making it easier to spot trends and analyze historical data for informed decision-making.

Benefits of Machine monitoring solutions

Real-time Performance Tracking

Ensure continuous monitoring of machine run time, idle time, and stop time, enabling swift responses to dynamic production needs and optimizing overall operational performance.

Shift-Specific Analysis

Focus on the current shift's data to gain insights into machine performance during specific operational hours.

Production Optimization

Optimize production by monitoring production during run and idle times separately, facilitating better planning.

Immediate State Recognition

Instantly recognize the machine's current state—whether it's running, idle, or stopped—for quick decision-making.

Graphical Trend Representation

Use graphs and trend data to visually represent machine performance trends, aiding in the analysis of historical data.